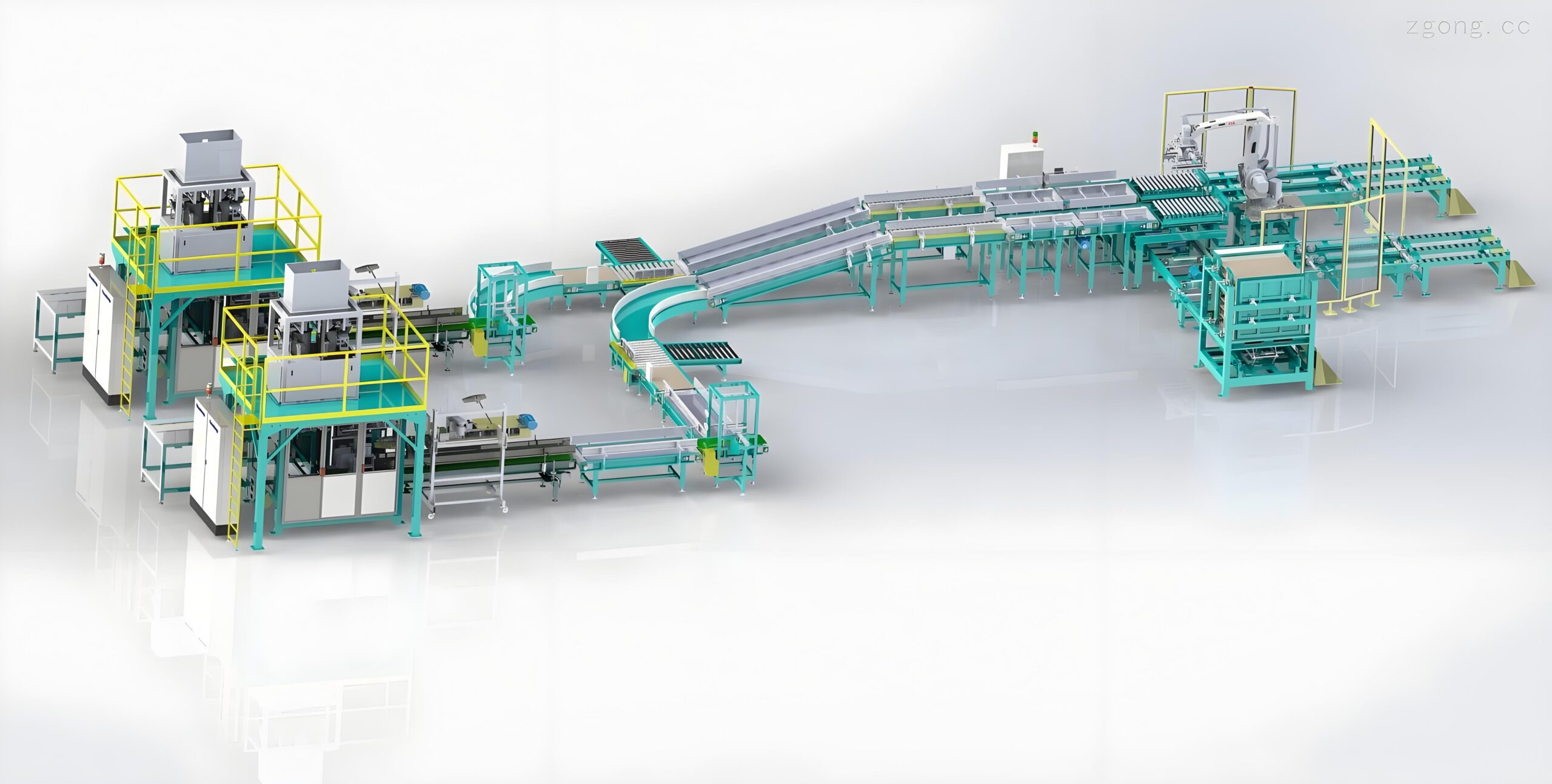

The robotic arm palletizing machine production line is a fully automated solution that integrates material conveying, intelligent sorting, precise palletizing, and warehouse management. Through the collaborative operation of multiple robotic arms and logistics equipment, it achieves an efficient closed-loop from product offline to pallet stacking. Its core consists of a high-speed conveying system, a visual recognition unit, a multi degree of freedom robotic arm group, and an intelligent scheduling platform, which can seamlessly connect with packaging machines, filling lines, or assembly line ends to complete continuous palletizing tasks for multiple categories and specifications of materials.

The production line adopts a modular layout design, flexibly configuring grasping tools (suction cups, grippers, clamps, etc.) according to material characteristics (such as boxes, bags, barrels, or irregular parts), combined with dynamic sorting algorithms and 3D visual guidance, accurately identifying material posture, size, and stacking priority, and optimizing grasping sequence and stacking path in real time. For high cycle production scenarios, multiple robotic arms achieve task allocation and collision avoidance linkage through a collaborative control system, significantly improving overall operational efficiency.

Intelligent management is the core advantage of production lines. The central control platform integrates IoT technology to monitor equipment status, material flow, and warehouse data in real-time, and supports remote parameter adjustment and fault warning. Flexible design enables it to quickly adapt to pallet specification changes, product changes, or mixed palletizing needs, significantly reducing production line switching time. In the fields of food and beverage, pharmaceutical packaging, chemical raw materials, and e-commerce logistics, this production line not only reduces manual dependence, but also improves warehouse space utilization through standardized stacking, becoming a key infrastructure for upgrading logistics in smart factories.