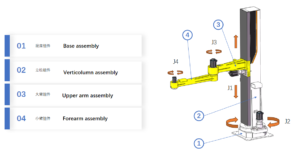

Unstacking&Feeding Robot

The Perfect Fusion of Space and Efficiency, Ushering in a New Era of Intelligent Depalletizing In modern industrial production, depalletizing operations, as a critical link, impose higher demands on space utilization, equipment stability, and operational efficiency. Our column-type palletizing robot breaks through traditional limitations with outstanding performance, delivering cost-saving and efficiency-boosting intelligent solutions for clients across multiple industries, including food and beverage, chemical, and water treatment.

High Space Utilization

Featuring a column-type design, the robot boasts a compact and refined body, excelling in low-ceiling environments and perfectly resolving layout challenges caused by spatial constraints with traditional equipment. This ensures every inch of factory space is utilized efficiently. Whether in narrow production workshops or storage areas with stringent spatial requirements, it adapts flexibly, freeing up more usable space for enterprises.

Simple Structure, High Stability

The streamlined mechanical structure reduces complex coordination among components, not only lowering maintenance difficulty but also significantly decreasing failure rates. Rigorous testing and optimization ensure stable and reliable operation, minimizing production interruptions due to equipment failures and providing worry-free production for enterprises. With no need for frequent downtime or repairs, substantial maintenance and time costs are saved.

Wide Applicability

In the food and beverage industry, it accurately grasps and smoothly depalletizes various packaged materials, ensuring hygiene and safety. In the chemical sector, its reliable performance guarantees safe and efficient handling of corrosive or hazardous materials. For the water treatment industry, it effortlessly tackles heavy, large-bag materials, facilitating smooth operations. From daily consumer goods to industrial raw materials, it adeptly meets depalletizing demands across different materials and environments.

Customizable Flexible Solutions

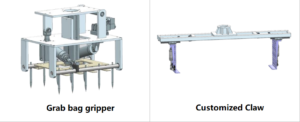

Our professional technical team tailors specialized gripping mechanisms based on material characteristics (e.g., weight, dimensions, packaging form) across industries. Whether for soft-package sorting in food or explosion-proof requirements in chemicals, modular designs enable rapid adaptation. Customizable parameters, such as production rhythm and working radius, are supported, and integration with existing MES systems ensures data interoperability. Truly, “one device fits one production line,” avoiding functional

Redundancy or performance gaps of standardized equipment

Choosing our column-type palletizing robot means opting for the perfect combination of space optimization, efficient production, and stable operation. It will become a powerful assistant in your enterprise’s upgrade and transformation, helping you seize opportunities in fierce market competition and create greater value.