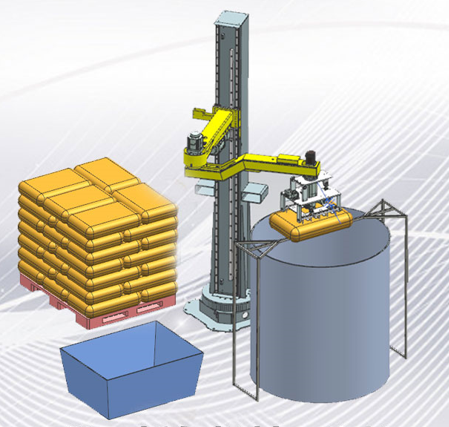

The palletizer bag unpacking and feeding workstation is the core module for achieving automated material processing in industrial production lines, designed specifically for efficiently and safely unpacking and conveying bagged raw materials. The entire system achieves unmanned operation through a modular structure and is suitable for bulk production lines in industries such as chemical, food, and pharmaceutical.

Core functional modules

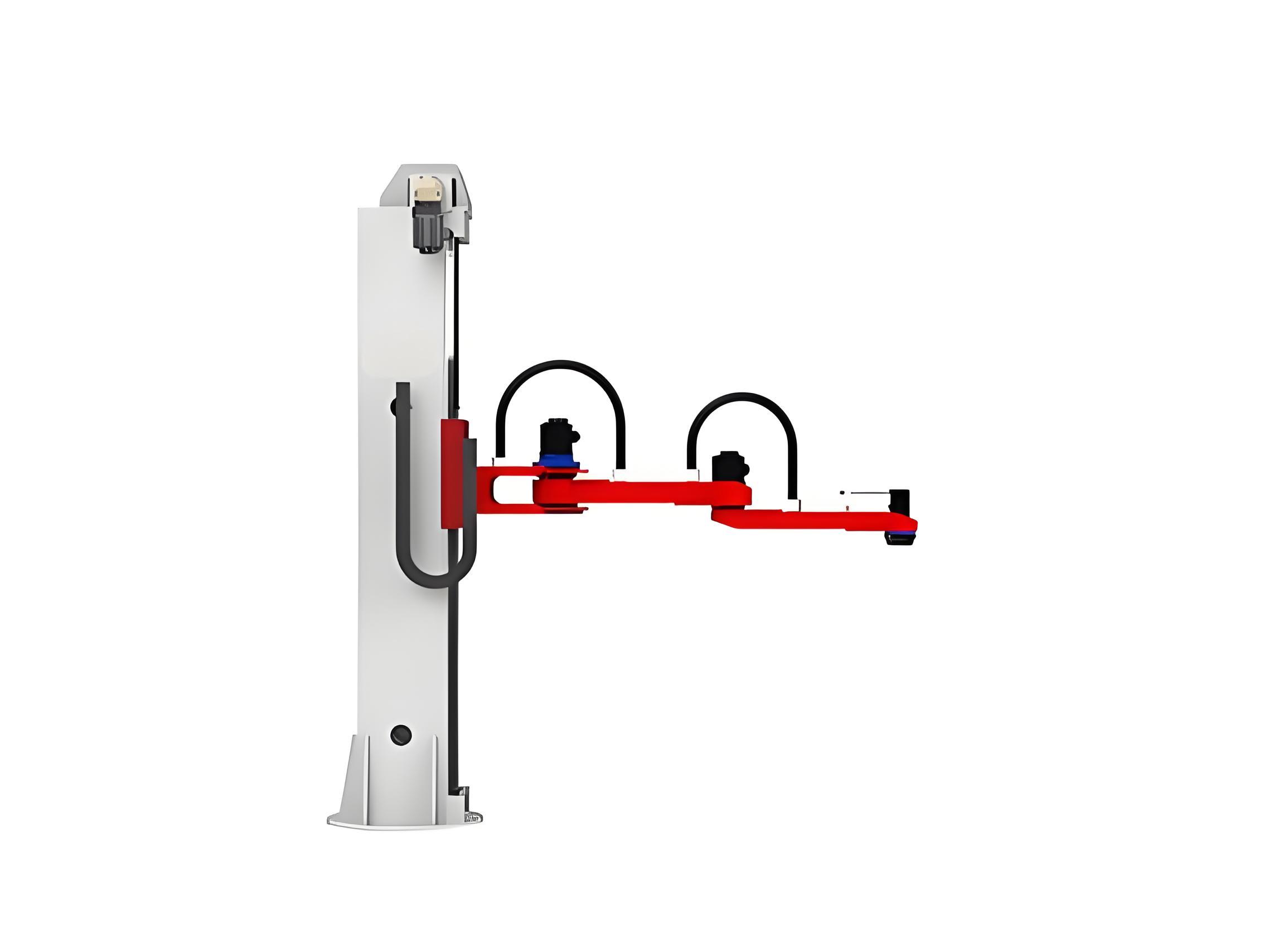

Automated unpacking unit: The robotic arm accurately grasps bagged materials, quickly peels off the packaging through flexible cutting technology, and cooperates with vibration devices to ensure complete detachment of materials. The empty bags are automatically separated and compressed for recycling.

Direct conveying design: The disassembled bulk material is directly fed into the receiving bin through a slide or guide groove, eliminating the need for intermediate transportation. The built-in anti blocking structure of the receiving bin is suitable for different forms of materials such as particles and powders to avoid blockage or residue.

Dynamic adjustment system: Intelligent perception of material flow, automatic adjustment of unpacking rhythm and conveying speed, ensuring efficient collaboration with downstream equipment and reducing waiting time.

Advantages of scene adaptation

Flexible scalability: Supports quick switching between various packaging specifications such as ton bags and small bags, adapts to the production needs of multiple categories, and reduces equipment adjustment time.

Efficient and low consumption operation: By integrating processes, material turnover paths are shortened, energy consumption and manual intervention are reduced, and overall production line efficiency is improved.

Safe and stable architecture: Key components are designed with industrial grade protection, equipped with emergency braking and operation monitoring functions to ensure long-term stable operation of the equipment.

This workstation highlights process simplification and intelligent collaboration, helping enterprises achieve efficient automation of raw material processing while reducing operating costs. It is particularly suitable for industrial scenarios that require high production continuity and flexibility.